DOWNLOAD

DATE

Contact

Nuclear power plant owners are hesitant to pursue life extension projects, and in some cases, are even shutting down their plants. As plants age and safety requirements inflate costs of life extension projects, nuclear plant owners often do not find these projects an attractive business case. This, combined with lack of political support, fear of national nuclear phaseouts, and competition from other (often renewable) energy sources, has forced the premature shutdown of several nuclear plants across the world. Arthur D. Little’s industry insight confirms that nuclear power plants run safely under normal circumstances, but don’t generally operate at their technical and economic optimum. To regain profitability and deliver the nuclear promise of a safe, reliable and economically convenient energy supply, the nuclear industry must improve. We believe a lean management framework to nuclear operations (“Nuclear Lean”) can bring significant performance improvements and cost reduction beyond 15 percent. This will help nuclear energy to stand its ground in the energy ecosystem of the future.

Nuclear energy is struggling as the energy market changes

The nuclear industry is at a turning point: as the energy markets embrace decentralization with renewable energies and cheap fossil fuels, nuclear is struggling to stay in the picture. Since 2013, in the United States alone, eight nuclear power plants have been shut down before their designed end of life. With them, approximately 6 GWe of baseload capacity were lost. This prevented the production of more than 20 million CO2 tons per year. Likewise, Germany and Belgium have decided to phase out their entire nuclear fleets by the mid-2020s.

Premature shutdowns are symptoms of an industry-wide trend with a variety of triggers. Below are three examples:

Lack of political backing: Because politics and the public in general are empowering renewables, nuclear power plants must be prepared for national phase-outs.

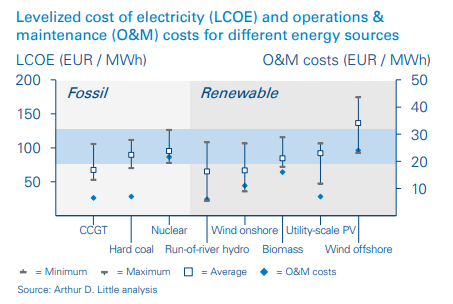

Limited economic competitiveness: With low carbon prices, nuclear has a higher levelized cost of energy compared to other thermal generation sources despite its positive impact on carbon emissions. (See below figure.) In addition, renewables benefit from subsidies and their technology prices are decreasing. These factors have resulted in a difficult position for nuclear within the generation portfolio.

Increasing safety requirements: Safety requirements imposed by national safety authorities are getting more demanding, and this is making it difficult for nuclear operators to justify the lifetime extension business case. This situation is often emphasized by issues with the aging workforce, which limits suppliers’ ability to deliver capital projects on time and on budget.

This lack of attractiveness to decision-makers will lead to shrinkage of nuclear in the global energy portfolio in the next years, despite aggressive new building in China and other emerging countries.

To counter these trends, the nuclear industry is already making industry-wide efforts, e.g., through the Nuclear Energy Institute’s (NEI’s) strategic plan, “Delivering the Nuclear Promise©”, and its efficiency improvement bulletins. Another example comes from productivity and optimization solutions developed by various players in the nuclear industry, e.g., Bruce Power’s Asset Performance Management (APM) system. However, these measures do not yet unlock the full cost-saving potential that has been observed recently in other high-reliability organizations, such as airlines, hospitals and semiconductors.

Efficiency potential in nuclear operations

The average energy availability factor (EAF) for nuclear power plants worldwide in 2015–2017 amounted to 82.2 percent (excluding the idle Japanese fleet). This includes a tail of poorly operating plants, whose EAFs can drop to under 70 percent. Arthur D. Little’s research on top-performing nuclear power plants shows significant room for efficiency improvement: bestin-class benchmarks can be found, e.g., in the US plant Dresden 3 and the Finnish plant Loviisa 1, whose EAFs reached 100 and 92.7 percent, respectively, in 2017. Likewise, the German Isar 2 plant has been among the world’s top 10 nuclear power plants several times, with more than 95 percent EAF.

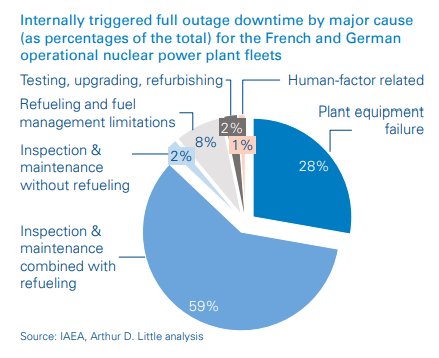

The above figure shows plant equipment failure and inspection & maintenance, combined with refueling, which represent more than 80 percent of nuclear plants’ internally triggered downtime. Both outage types involve complex processes concerning several activities and departments. Task management is complex and inefficiency may result.

However, in stark contrast an EAF close to 100 is possible even in older facilities, as benchmarks such as Dresden 3 show Arthur D. Little research shows that internally triggered downtimes beyond technical constraints often originate from how the plant is managed and what performance culture exists beyond safety. This is well in line with other industry examples, and leads to substantial cost-saving potential that usually does not collide with safety constraints.

Lean management in safety-driven industries

Lean is a leadership and organizational concept to systematically avoid waste, failures and unnecessary cost. Originally having evolved in automotive manufacturing, it became a general leadership approach for any kind of operational and administrative business process, and is now often labeled “lean management”. It has focused on creating value and establishing a “zero-failure” philosophy, while avoiding redundancy by optimizing alignment of activities. Because of this, lean management has generated increasing awareness in safetydriven industries in the last years (e.g., the process industry, aviation and healthcare). Observed lean activities have led to substantial downtime reductions, which has brought plant performances up to levels of best-in-class plants (more than 90 percent. These practices have also achieved significant cost savings (frequently exceeding 15 percent), shorter lead times, and increased process compliance.

Arthur D. Little’s Nuclear Lean framework focuses on performance improvement in nuclear operations, respecting the necessary safety principles and general safety culture requirements. Our approach combines performance improvement with long-term leadership and capability building to meet competitive energy market challenges. Compared to traditional, and often failed, method-based lean concepts, our framework strives to build sustainable lean governance.

Closing the efficiency gap

Nuclear benchmark plants improve their performances by continuously synchronizing their nuclear operations processes and professionalizing their failure prevention routines.

End-to-end process management

Minimizing idle capacities in plant operations promises efficient, reliable plans and schedules for inspection and maintenance. They need to be designed with a holistic approach, integrating processes from planning and scheduling (work management, materials services) to execution (plant operations).

Process optimization efforts should focus on reducing the overall lead time by eliminating non-critical idle time. New efficiency potential can be realized through end-to-end process harmonization (e.g., plant outage due to corrective maintenance of failed equipment). This overcomes cross-functional and cross-organizational silos with management supervision and end-to-end key performance indicators (KPIs). To achieve this, role definition and implementation of “process management” to monitor and steer process performance improvement is fundamental.

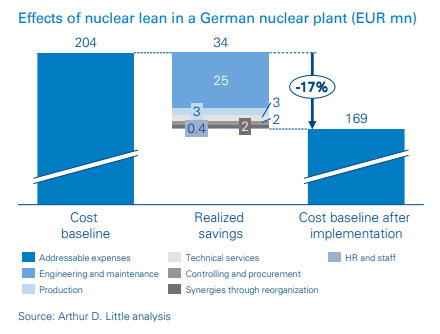

Arthur D. Little has exhaustive experience in the nuclear industry, as we have already addressed the application of lean management concepts to nuclear plants. For instance, we applied these concepts in a performance improvement project for a German nuclear plant operator. During the project, Arthur D. Little restructured the client organization according to lean principles, moving from a systems-oriented organization with departments such as “mechanical maintenance” and “electrical maintenance” to a new structure that encompassed end-to-end processes. This new organization followed the logic of end-toend processes such as “production”, “technology” (covering, e.g., engineering and maintenance), “technical services” (covering, e.g., radiation protection) and “commercial services”. This helped the client to reengineer its business processes and identify 34 EUR mn in waste, namely, 17 percent of total addressable costs, which were sustainably saved. (See below figure.)

Problem-solving: Root-cause analysis and optimization

Reducing plant equipment failures and outage time requires a continuous process of problem solving. As effect and root-cause are often detached by a temporal and organizational gap, the problem-solving process should bring involved functions and organizational departments together.

A main responsibility of the project manager is systematic root-cause analysis and optimization implementation. Rootcause analysis should be applied beyond technological aspects to address process inefficiencies and identify optimization opportunities. An example is the total outage downtime for maintenance and repair, combined with refueling. Tools such as fishbone analysis and best-in-class benchmarking can identify root-causes forcing downtime overextensions (e.g., inspections that can be executed in service, poor planning and problem anticipation attitudes). Efficiency can increase through identified improvement measures, and ad hoc established KPIs (e.g., total downtime extension caused by poor planning) can monitor the results.

Implementing continuous improvement

Nuclear benchmark plants are driven by a mind-set of continuous improvement, which fits very well with the lean management approach. From our perspective, a viable nuclear lean organization is built on three pillars:

- Leadership, to clearly formulate expectations and help introduce an effective management and delegation culture, which will lead to continuous improvement.

- Target establishment, to define concrete objectives in the performance of the end-to-end processes and monitor it through tailored KPIs, which will assure the effectiveness of the introduced measures (e.g., average downtime).

- Use of continuous improvement (“Kaizen”) platforms, to set up a culture of perpetual improvements through small optimization steps and address the right problem with the right set of employees.

Nuclear power plants will achieve sustainable improvements in process times and compliance through application of all elements of our nuclear lean framework. This will lead to savings in operations and maintenance costs.

Continuous improvement: “Kaizen platforms”

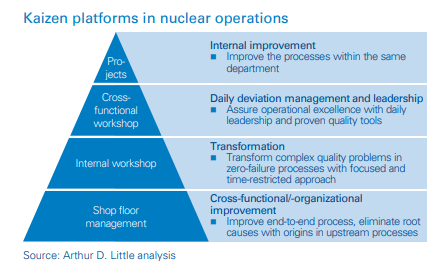

Depending on the individual improvement needs of the nuclear operation, there are different options for improving its current state. The right Kaizen platform is selected according to the size and importance of the efficiency gap. Although daily routines can address smaller improvement needs while following a sustainable continuous improvement approach, larger issues need to be delegated, for example, to dedicated teams. Establishing continuous improvement as a daily routine not only leads to involvement of the entire plant’s workforce, but also ensures that the changes will be sustainable. However, integration of continuous improvement into work routines is limited to smaller issues. Complex topics must be delegated to assigned work groups and followed up accordingly. An example is very small improvement tasks resolved in daily shop-floor management, versus scheduling optimization designed in crossfunctional, end-to-end process workshops. (See figure the on the next page.)

The following aspects need to be emphasized:

- Daily performance management needs to be established based on forward-looking steering KPIs.

- Daily performance dialogues must become the main platform for daily deviation management. If possible, measures for problem solving should be defined here.

- Standardized, end-to-end-workshops should become the main cross-functional performance improvement platform.

Developing the Nuclear Lean capability

Developing the required capability and establishing the necessary management system throughout the organization remains a top-management issue. It must ensure commitment and communication to “live lean” and ensure cultural change. This is achieved through process-oriented, cross-functional workshops, continuous improvement via Kaizen platforms, and root-cause elimination. Top management must, however, be aware of cultural challenges in the implementation of a new management system in a routine-based environment. It must also be ready to promote comprehensive workforce involvement. Numerous projects show that top-management awareness of lean management and its holistic implementation remain one of the most crucial success factors regarding achievable performance improvements.

Conclusion

Safety targets and standardized procedures are clearly defined and usually obeyed carefully within nuclear power plant operations (e.g., EUCG’s Standard Nuclear Performance Model). Nevertheless, targeting specific processes within routine operations by applying lean management can lead to significant availability increases and, subsequently, lower operating costs. At the same time, the company does not have to sacrifice safety or sustainability

Arthur D. Little’s Nuclear Lean framework provides a holistic approach, which focuses on sustainable performance improvement in safety-driven environments through its zerofailure philosophy principle.

The operational core of Nuclear Lean focuses on end-to-end optimization of nuclear operations and cross-functional problem solving. This operational core is embedded in a holistic concept, in which performance improvement is realized in Kaizen platforms for continuous improvement.