The industrial sector has always been the backbone of strong nations and a key development focus for humanity. Today, complex innovations are catapulting the industrial sector to new heights. The task at hand is to ensure that the sector maintains its pace in a sustainable manner, creating a balance between economic growth, environmental care, and social well-being. The Kingdom of Saudi Arabia (KSA) showcases a country that has the opportunity to lead by example.

REVOLUTIONARY CHANGE: FROM ELECTRICITY TO AI

Building on the legacy of the first three industrial revolutions, the Fourth Industrial Revolution (4IR) — also known as Industry 4.0 — is opening a new chapter in the story of humankind. Powered by advanced intellectual property, knowledge economies, and state-of-the-art technologies, including artificial intelligence (AI) and the Internet of Things, 4IR is disrupting every economic sector at a blinding pace and transforming the way organizations and governments operate.

This new revolution brings a complex portfolio of digital, physical, and biological assets and offers an unparalleled opportunity for human development. But there is a caveat: if not sustainably managed, 4IR will come at a hefty price; today’s supercharged pace of industrial production is accompanied by a drainage of resources and rising emission levels. A question hence arises: how long can our environment maintain such exponential industrial development?

The answer is still unknown, but it will depend on the actions of key stakeholders. With the clock ticking, Arthur D. Little (ADL) has identified several dimensions across the industrial value chain that organizations should tackle to ensure sustainable growth.

SUSTAINABILITY DIMENSIONS IN THE PRIVATE SECTOR

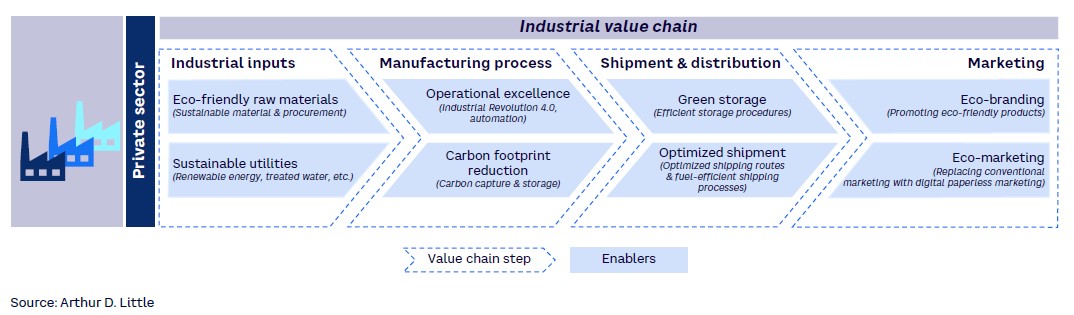

Industrialists are delivering significant efforts toward sustainability throughout the private sector, with leading multinational companies implementing measures across their value chains. Figure 1 breaks down the links of this “industrial value chain,” which we explore in depth below.

1. Sustainable industrial inputs

When the COVID-19 pandemic struck in early 2020, it unearthed weaknesses in global industrial supply chains, demonstrated severe shortages of vital materials, and created panic among manufacturers. Now, an even greater challenge is emerging vis-à-vis environmental sustainability. Examining how industrial companies use energy, and obtain and use consumables, offers a logical area to begin building a strong sustainability plan.

Energy is essential to industrial operations; addressing its role in industrial development is necessary to a successful strategy. Conventional sources of energy, which typically includes hydrocarbons or electricity generated by nonrenewable sources, are responsible for approximately three-quarters of greenhouse gas (GHG) emissions, according to the US Energy Information Administration. Transitioning from these environmentally damaging sources to renewable energy alternatives is a critical step toward increased sustainability.

Because switching to low-carbon energy sources is an imperative, industrial facilities should reassess their energy mix and implement more environmentally friendly options, which include choosing biomass and manufacturing residuals over fossil fuels and relying on solar and wind power.

In addition to choosing cleaner types of energy, businesses must evaluate the materials they use and consider whether or not they can make better choices for the planet. Using eco-friendly raw materials and shifting toward sustainable procurement are important steps on the quest for sustainability. Making use of recycled materials and producing recyclable items are also critically important. Manufacturing can generate a significant impact on the private sector’s long-term sustainability by applying circular principles and considering the role of recycling when designing and sourcing products. Additionally, sourcing closer raw materials saves transport emissions and the way you transport them (i.e., larger trucks, larger vessels, or bio-/EV-powered trucks) would significantly reduce emissions as well.

IKEA’s sustainability strategy is a leading example of how to promote eco-friendly practices. The global home furnishings company has started sourcing half of its wood from sustainable foresters and plans to adopt a 100% renewable energy policy in its stores by 2030.

2. Refined manufacturing processes

According to the World Government Summit, more than 30% of total GHG emissions are generated by industrial processes. Focusing on improving industrial manufacturing processes is proving to be significantly impactful — improving the energy efficiency of industrial processes could result in reducing manufacturing emissions by 8%.

Leading industrial countries are accelerating their investments in cutting-edge technologies. Collaborative intelligent machines and robotics, and self-learning cognitive systems are proving to be essential to achieving operational excellence inside the plants. Additionally, carbon capture and storage and smart energy systems are key technologies adopted by the plants to reduce their carbon footprint. Also, there is growing potential in improving efficiency though the management of heat recovery and pressure adjustments. Moreover, big data, connected things, and virtual modeling and simulations are leading to both operational excellence and carbon footprint reduction. Growing investments have been made in funding Industry 4.0 programs with an emphasis on advanced technologies and initiatives designed around innovation and productivity. In fact, according to Invest Saudi, KSA is supporting a digitally enabled industrial revolution for projects across different industries, including mining, industry, logistics, and energy through a US $453 billion fund.

Industrial facilities can reduce their carbon footprint by implementing practices to refine their manufacturing processes and make them more eco-friendly, including:

-

Follow Lean production principles, also known as “no waste by design.”

-

Strive for operational excellence to improve efficiency in the various stages of the manufacturing process.

-

Promote a holistic “reduce, reuse, recycle” philosophy.

-

Ensure technology and configuration optimization.

-

Improve energy efficiency through heat recovery and minimizing energy losses.

Automaker BMW has been setting an example in this sphere by actively introducing automation and intelligent advanced systems in several of its manufacturing facilities, which has led to a 30% decrease in resource consumption and emissions over the last 10 years.

3. Efficient shipment & distribution

On top of industrial inputs and manufacturing processes, shipments and distributions of manufactured products are proving to be key contributors to the sector’s emissions. Shipping and distribution can be optimized by rolling out green storage logistics, adjusting routes, and applying fuel-efficient processes.

UPS, a leading logistics company, has introduced new trucks powered by compressed natural gas and is working to eliminate excess mileage and reduce fuel consumption by using pioneering technology, such as satellite-optimized route planning.

4. Green marketing

Eco-marketed products, or products that are labeled as environmentally friendly, are experiencing significant growth, thanks to consumers who are more willing to pay premium prices for “saving the environment.” For instance, in the UK, spending in this segment has increased almost tenfold in the past 10 years, while household spending decreased over the same period.

Adopting reusable packaging practices is another way manufacturers can reduce their carbon footprint. Most notably, replacing single-use plastic with eco-friendly alternatives benefits the environment and saves money for companies. Promoting eco-friendly products and shifting toward practices like paperless marketing can help industrials earn a sustainability edge. Consumers are increasingly expressing a preference for eco-friendly alternatives, which can also make green marketing profitable.

SUSTAINABILITY DIMENSIONS IN THE PUBLIC SECTOR

Industrial giants are leading by example by demonstrating how private stakeholders can make a positive impact when it comes to sustainability. However, without governmental enablement, their efforts remain limited. From supporting green practices to imposing eco-friendly requirements and regulations, governments have the power to initiate, accelerate, and — when necessary — enforce, plans and policies across the sustainability spectrum.

As the Gulf Cooperation Council’s (GCC’s) largest industrial powerhouse, KSA is committed to building a greener future. The Kingdom launched a large number of initiatives across the different economic sectors and specifically in its industrial sector, including initiatives on:

-

Supporting nationwide green incentives.

-

Promoting environmental transparency as a strategic priority.

-

Establishing public-private sustainability partnerships.

-

Enforcing eco-friendly licensing requirements.

-

Maximizing regional collaborations and synergies in the energy transition.

-

Enabling the development of small and medium-sized enterprises (SMEs).

The Kingdom is home to more than 10,000 industrial facilities and ranks 41st in the Competitive Industrial Performance Index. It is proving to be a rapidly growing industrial force. There are six important dimensions within the public sector where changing practices or adopting new approaches can support sustainability goals.

1. Nationwide green incentives

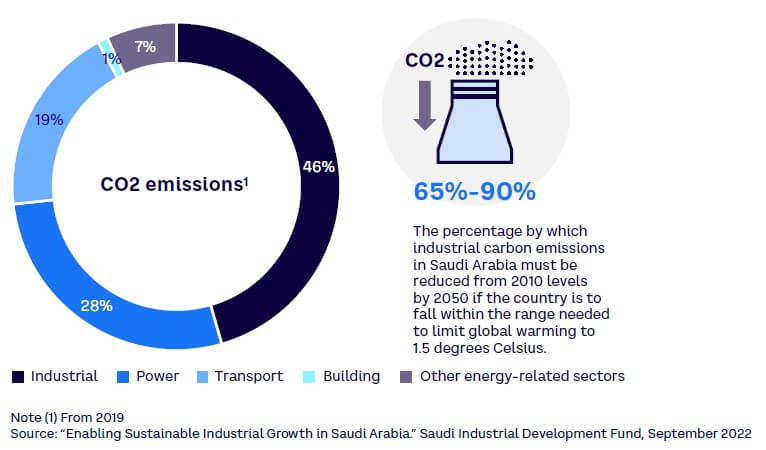

KSA is leading the transformation of the industrial and mineral resources sector through the Ministry of Industry and Mineral Resources Sustainability Council (MIMSC) and is working to secure funding for green transformation projects in industrial facilities. The Kingdom has implemented ambitious targets for the future, aimed at reducing industrial emissions by 65% by 2050.

The industrial sector of the Kingdom is responsible for around 46% of the country’s total emissions, ranking it as the most emitting sector, followed by power generation at 28%, and transport at 19%. Figure 2 shows specific percentages of emissions, organized by sector.

The government has launched the Liquid Fuel Displacement Program, a large energy transformation project covering multiple sectors. The project aims to displace more than one million barrels per day of liquid fuels across utilities, industry, and agriculture by 2030, involving more than 10 governmental entities and more than 20 private companies. This program will enable the Kingdom to realize its ambition of deriving 50% of its electricity from renewables by 2030, while also reducing its GHG emissions.

Aside from reducing emissions, the government is also working to move the industrial sector away from fresh water. There are 16 industrial cities in the Saudi Authority for Industrial Cities and Technology Zones (MODON); the government aspires to source 70% of their water from treated industrial waste water by 2030.

2. Prioritized environmental transparency

One of MIMSC’s early main strategic goals was the widespread adoption of environmental indicator reporting. This goal was rooted in the council leadership’s understanding of reporting as both a key enabler of effective compliance and a tool for investment attraction. MIMSC is developing a set of voluntary reporting standards aligned to the specific structure and conditions of the Saudi economy, particularly in relation to the SME landscape. These standards are intended to boost foreign investment, ensure long-term environmental sustainability, and catalyze participation in nationwide endeavors, such as the Saudi Green Initiative. In this regard, the Saudi Industrial Development Fund (SIDF) is uniquely positioned to contribute to the task by leveraging its knowledge of the Kingdom’s evolving industrial fabric and sharing its perspectives as a sustainability-minded lender.

3. Public-private sustainability partnerships

MIMSC is playing a key role in synchronizing private and public sector sustainability efforts. First, MIMSC gathers input from leading Saudi companies, which include Saudi Aramco, SABIC, and Sadara, and public entities working closely with SMEs, including SIDF and MODON, to ensure new policies represent a corporate perspective. Second, MIMSC contributes to the sustainability-oriented technological and organizational adaptations of the industrial and mining ecosystems by publicly supporting companies that set best practices, introduce innovation-related initiatives, and foster knowledge sharing. To accomplish this, MIMSC will seek to broaden the participation of corporate players on its board in the future.

4. Eco-friendly licensing requirements

The Kingdom is revamping its industrial licensing requirements by mandating criteria to promote the adoption of advanced technologies to increase manufacturing efficiency and help reduce GHGs.

5. Maximized regional collaborations and synergies

The Saudi government is unifying the region’s efforts through consistent collaboration between GCC countries, aiming to boost the sustainable development of industrials and synergize the region’s fight against climate change. This includes efforts to reduce GHG emissions, implement waste management solutions, and raise awareness of industrial sustainability. The Kingdom’s efforts have been incorporated into a joint plan with GCC countries to adopt the concepts of circular economy within the industrial sector. The plan aims to ensure that the percentage of industrial facilities adopting circular economy practices reaches at least 50% of all industrial facilities within five years in each of the GCC countries.

6. Incentivized SMEs

SMEs constitute around 90% of the Kingdom’s industrial sector, and KSA is supporting them by providing incentives and services to enable their sustainable development. These incentives include promoting the use of efficient technologies that reduce waste and securing funding for green-oriented start-ups. This will lead to sustainable manufacturing operations and promote the adoption of environmental, social, and corporate governance.

Conclusion

TOWARD A SUSTAINABLE FUTURE

Growing regulatory pressure and consumer environmental awareness have transformed sustainable industrial development from a strategic option to a necessity for both private companies and governments. However, despite massive commitments to achieve long-term carbon neutrality, ideally by 2050, countries are still far from meeting their industrial sustainability goals. To achieve tangible progress, governments are partnering with the private sector to accelerate the execution of industrial sustainability plans. The KSA government is launching nationwide green incentives and eco-friendly licensing requirements, while maximizing regional collaborations and synergies in the realm of industrial sustainability. Furthermore, industrialists in the private sector are actively incorporating sustainability components in their corporate and business strategies, ensuring effective sustainability measures are being adopted across their industrial value chain. This will create long-lasting impact and chart the course for a sustainable future.