Globally, companies rely on large fleets of cars, trucks, vans, and specialized vehicles to keep their operations and people moving. Both vehicle numbers and fleet management complexity are increasing, particularly as organizations plan to decarbonize and move to alternative powertrains, such as electric vehicles (EVs). Traditionally, optimizing fleet management has not been a business priority. However, this Viewpoint addresses how cost, complexity, and sustainability require organizations to be more proactive.

UNDERSTANDING THE FLEET MANAGEMENT LANDSCAPE

Organizations across different sectors depend on their fleets, whether they’re in the business of energy, water, logistics, waste management services, or telecoms. Their fleets, which may include company or pool cars, trucks, vans, or specialized vehicles, are essential to effective operations. Fleets can comprise thousands of vehicles of multiple types, with maintenance and support split between in-house facilities and a network of ecosystem partners. There is little transparency about the real costs of internal maintenance operations, and fleet management teams are often relegated to a coordinating role, with budgets and control in the hands of individual departments.

Despite their size, fleets are not a substantial item on the balance sheet, especially when compared to assets like production plants, power stations, and distribution centers. Consequently, optimizing fleet activities has not been a management priority until now, except around myriad tactical issues (e.g., unused vehicles, lack of vehicle availability, or failure to deliver the necessary functionality). However, better fleet management is business critical, thanks to digitalization, the growth of fleets in size and scope, the need to increase cost efficiency and transparency across all operations, and the impact of switching from internal combustion engines (ICEs) to sustainable powertrains, which are driving an enormous rise in complexity and cost.

Challenges to fleet management

Arthur D. Little’s (ADL’s) client engagements reveal seven key challenges that may arise while optimizing the management of large corporate fleets:

- Companies do not have a transparent, comprehensive picture of either supply or demand due to lack of data for assets within their fleets and their utilization levels.

- There is no corporate overview of needs; new vehicles are ordered and tailored based on requests from departments rather than aggregate demand, leading to poor utilization levels, high vehicle redundancy, and a lack of basic standardization.

- Costs are higher due to inconsistent evaluation of buy-versus-lease decisions, fleets with diverse service needs, and complex procurement.

- Managing internal maintenance and repair facilities (especially for specialized vehicles) adds to costs and potential inefficiencies compared to other maintenance options and additional expenses.

- There is a need to incorporate EVs into the portfolio, which drives required investments in new charging infrastructures, processes, and maintenance capabilities.

- Heavy and/or inconsiderate vehicle usage creates high demand for repairs and maintenance since drivers know all issues will be fixed without any downside for themselves. Fleet sizes are also growing due to the increasing use of company and pool cars, creating additional demand for maintenance and repairs.

- Finally, a wide range of vehicle types and specifications make it difficult to standardize maintenance and repair activities.

TRANSFORMING FLEET MANAGEMENT

Tackling the above challenges requires organizations to implement a more balanced, digital, proactive, and transparent framework for fleet management. A well-developed approach improves the likelihood of increasing operational efficiency, reducing costs, and meeting objectives (e.g., decarbonizing transport options). The focus must be on the fleet itself, fleet management capabilities, and internal maintenance facilities.

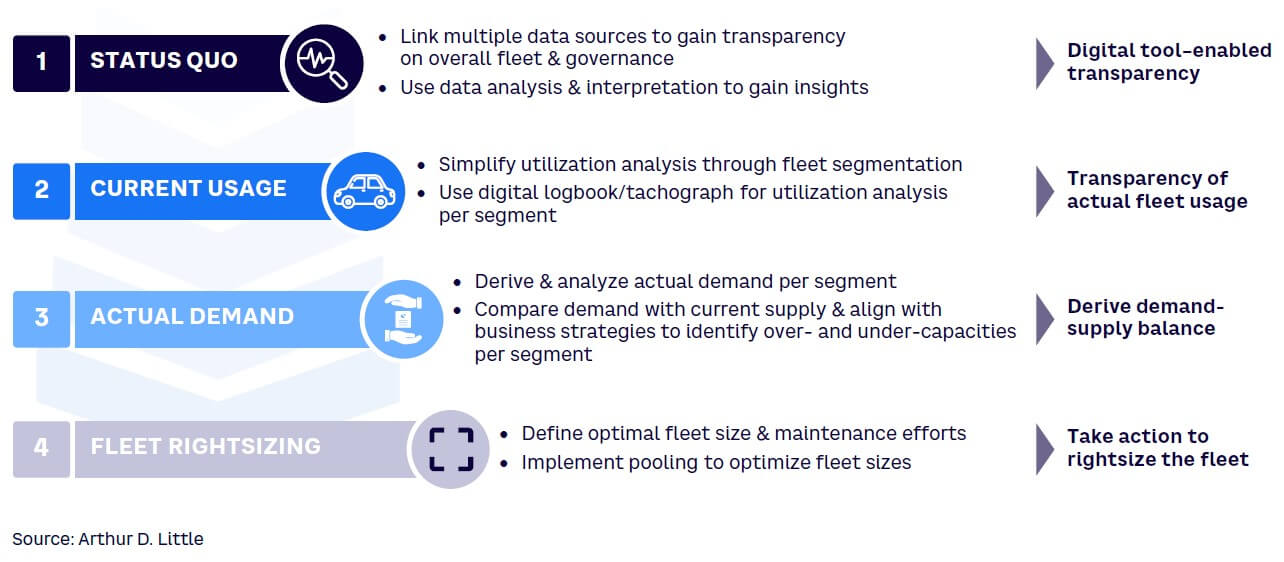

ADL has created a four-step framework, summarized in Figure 1 and expanded upon below, to drive fleet management transformation by digitizing operations, increasing transparency, and better balancing supply and demand. This framework is applicable for both organizations with a diverse, specialized fleet (e.g., utilities or telecoms companies) and those that have a generalized fleet (e.g., logistics and maintenance providers).

Step 1: Status quo

Businesses often do not have a clear picture of their overall fleet, given that departments drive the requests to purchase and use vehicles. In particular, businesses lack detailed information on the number of vehicles within specific categories (e.g., small passenger cars, specialized trucks), their financial value, their procurement, and what contracts are in place. Without this information, it is impossible to make informed decisions about retiring, repairing, and/or replacing vehicles, rightsizing internal maintenance facilities, or making choices on using external suppliers. To achieve a holistic, exact view of assets, organizations should collect and cross-reference data from multiple sources to overcome any issues with data accuracy caused by poor processes or lack of oversight.

While traditional tools have their purpose, deploying data analytics and AI solutions supports the collection and understanding of a much wider range of data points across contracts (with leasing or maintenance providers) and the vehicles themselves. Key people get a clearer, more transparent view, which leads to better decision-making. Clustering similar vehicle types together provides a higher-level view, helping understand potential overlaps. Alongside data collection, the right governance processes need to be put in place. Senior management must support the move to a more centralized fleet management approach; implement digital fleet management systems (see sidebar); and put a trained, proactive centralized team in place.

Digital fleet management solutions

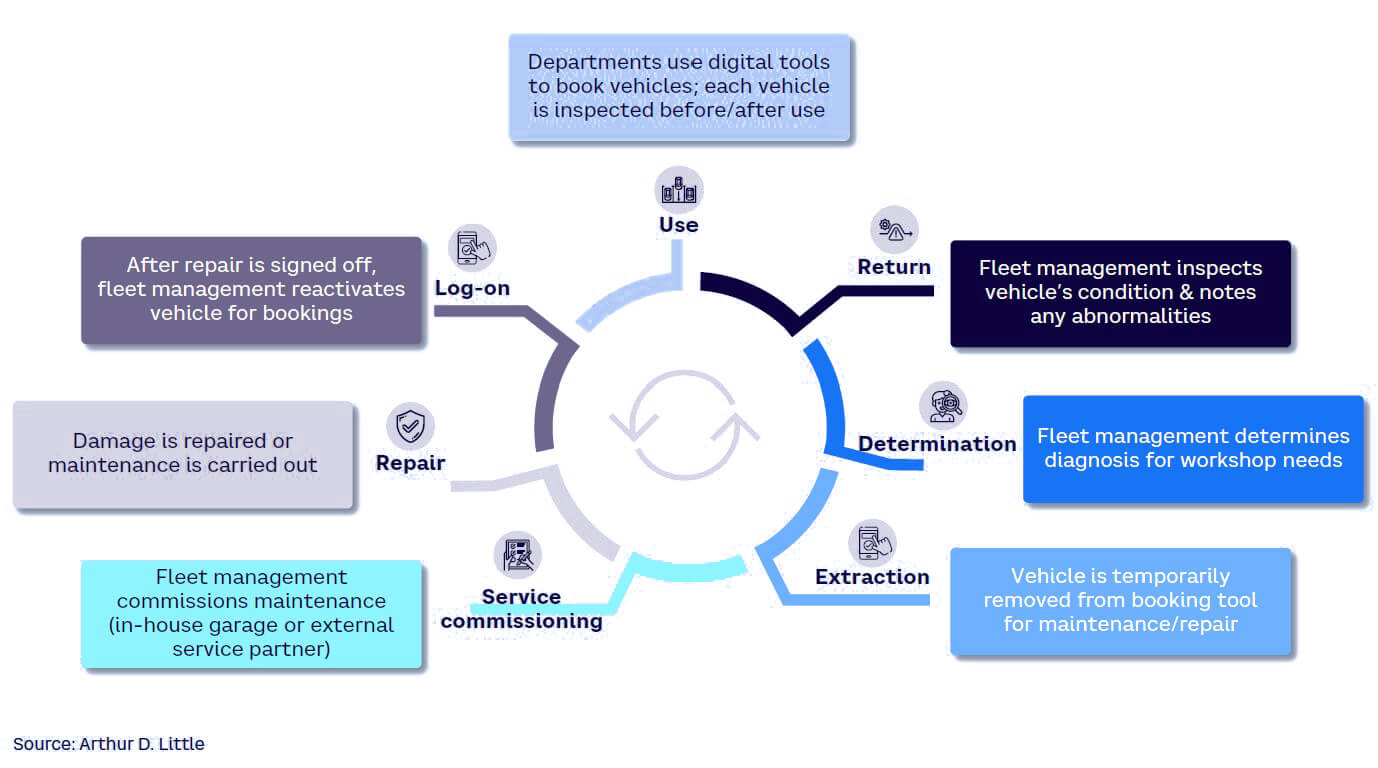

Digital tools help organizations manage their fleets end to end, collecting information on usage, making self-service booking available, flagging when maintenance is due, and handling processes for necessary repairs (see Figure A). Digitalization begins when vehicles are added to the system, creating a virtual profile populated with data provided from a connection to a digital logbook/tachograph. Data can be updated in real time (e.g., current location, distance traveled). The profile also contains comprehensive information on maintenance cycles, repairs, and any leasing or service contracts linked to the vehicle. This supports proactive management of the fleet and provides the foundation for improved utilization.

Employees access the system securely, based on job role and corporate access rights, so they can view/book relevant vehicles and related equipment through a user-friendly interface. If a particular vehicle is unavailable, the tool automatically offers an alternative from an equivalent or higher segment, based on the understanding that larger or higher-specification vehicles can be deployed for journeys with lower requirements. The fleet management system underpins the entire utilization process, including maintenance and repair cycles, which are either triggered automatically based on rules or manually after vehicle inspection. Digital tools also feed into wider business management (e.g., CO2 reporting for sustainability).

Step 2: Current usage

In addition to building a picture of the total fleet, companies need to identify current usage of vehicles. The process starts by collecting and combining digital logbook/tachograph information on when assets are being driven, the distances traveled, and how these details (peak and low-usage times versus consistent, constant use) change over time. We recommend a minimum one-year data collection period to cover peaks and troughs. By taking a fleet-level view of usage, broken down by vehicle categories, organizations can create a realistic picture of actual current usage and how it changes over time. Then, they can assign percentage-utilization figures for individual vehicles and wider segments and highlight any particularly underutilized assets.

Step 3: Actual demand

When ordering vehicles, departments build in redundancy and additional capacity to their specific fleets and in-house maintenance operations. While these actions are rational from a business continuity perspective, they lead to overcapacity and lack of synergies between different parts of the business. It is therefore vital to analyze and understand actual demand at the overall and vehicle category levels. Vehicle demand should align with business strategy; for example, if organizations expand into new areas or offer new services, will these changes impact fleet requirements going forward?

Step 4: Fleet rightsizing

By combining demand and usage data, businesses can accurately define the optimal size for their fleets and the internal maintenance resources they require. This information should be broken down by vehicle type and segment, based on both peak and normal demand per day and week, delivering the specific number of vehicles required. In addition, organizations need to set realistic usage targets that consider factors such as maintenance, repairs, and events (e.g., accidents), which may limit vehicle availability. After reviewing the data, use a pooling approach to make the most of fleet sizes.

Pooling allows companies to move away from business units having exclusive ownership and access to specific vehicles. Instead, a single fleet becomes available to all departments and employees. Vehicles are reserved using digital booking solutions, with departments and users sharing access to the complete corporate fleet. The use of pooling reduces ownership costs, enhances convenience, and promotes sustainable usage by optimizing vehicle utilization. If a requested vehicle is not available, a relevant alternative is provided, delivering flexibility and minimizing the number of vehicles standing idle.

Defining the right fleet size to provide enough vehicles for business demands is a delicate and political balancing act, even when logbook analysis and tachographs show that current fleets cover above 100% of demand. Analyzing data to inform changes to the mix of available vehicles and removing vehicles from the ownership of business units are two options for reducing the number of available vehicles.

Multiple ADL client interactions have informed some best practices. Below we highlight four potential models for optimizing fleet size, with different levels of savings provided:

- Cover 100% of peak demand for every vehicle segment at all times. Fleet size will remain high, delivering little or no savings potential as off-peak utilization levels can be low on a per-vehicle basis.

- Cover 80% of peak demand for each segment and subsegment at all times to increase efficiency and reduce fleet size, but that means there will be some occasions when a relevant vehicle is unavailable. This scenario can be minimized through advanced digital booking systems and active fleet management.

- Implement pooling within individual vehicle segments, which will cover 80% of peak demand per segment. When a vehicle in a segment is unavailable, an alternative from a higher segment can be provided through the pool (e.g., a passenger van instead of an SUV).

- Set coverage at 80% across all segments and implement company-wide pooling. This is the most advanced setting with the highest potential for savings; it is the most efficient but also requires the highest flexibility from users and highly active management by the organization.

These four models are really evolutionary steps, enabling the company to slowly decrease its fleet size and expand the use of pooling. Taking a step-by-step approach has cultural and adoption benefits as it allows employees to become familiar with the new system over time, which increases acceptance of change.

In addition to rightsizing fleets through pooling, companies can also outsource fleet management to one or more external service providers. The business maintains ownership of the vehicles and their leasing contracts while the service provider takes care of fleet management and maintenance, charging on a per-vehicle, per-year, or per-transaction basis. Users book vehicles through the service provider’s digital solutions.

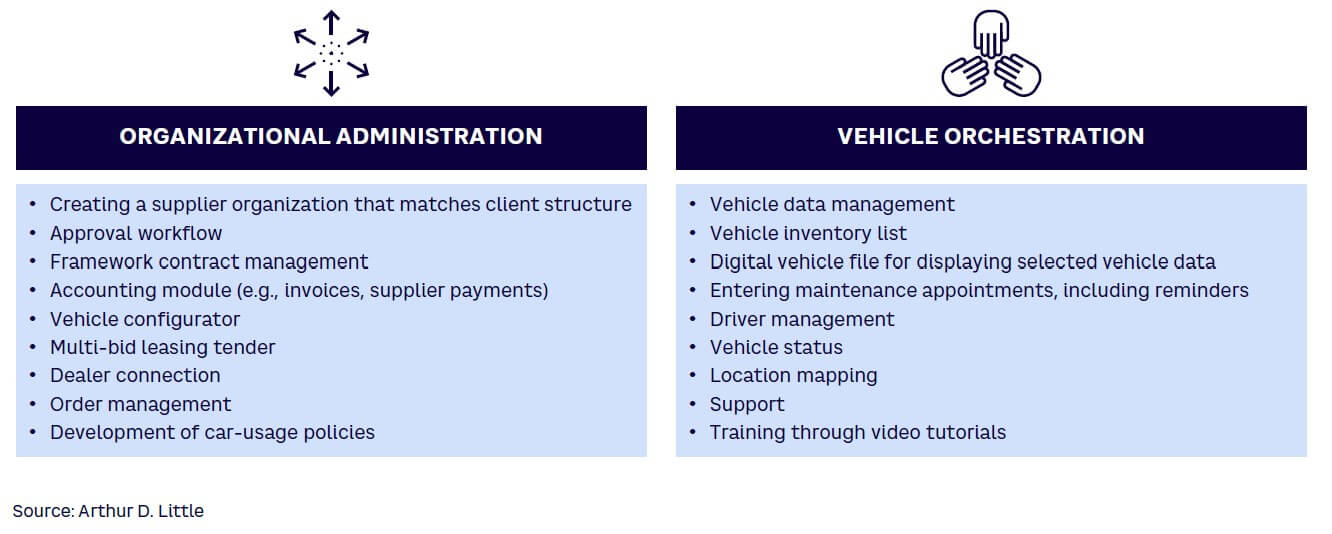

However, while this can reduce costs and management time, it often requires companies to adopt the standard procedures and processes offered by the service provider, potentially damaging flexibility. Thus, the organization must manage the provider to ensure performance meets service-level agreements (SLAs). Figure 2 illustrates typical offerings from external service providers.

REAPING THE BENEFITS OF OPTIMIZED FLEETS

Maximizing fleets and in-house maintenance operations delivers four clear benefits: (1) cost reduction, (2) a rejuvenated fleet, (3) a sustainable fleet, and (4) stronger digital governance.

1. Cost reduction

Decreasing the number of vehicles in the fleet while still meeting demand clearly lowers costs, as does digitalizing fleet management itself. When removing vehicles from the balance sheet, there is a savings with ongoing expenses of operating costs (tax, fuel, parking, maintenance). Having a better understanding of the overall fleet also enables businesses to reduce demand for internal maintenance operations. Moreover, standard processes (e.g., passenger car servicing) can be outsourced to partners, allowing internal teams to focus on complex, specialized vehicles where they have the strongest knowledge and experience. Internal maintenance garages can be rightsized to execute specific activities, further reducing costs.

Based on our experience, potential cost savings include:

- 15%-25% fleet-size reduction, leading to 8%-12% budget savings

- 10%-30% reduction in administrative costs

- 15%-50% decrease in maintenance costs

- 10%-20% total cost savings

2. A rejuvenated fleet

Removing older, less reliable vehicles improves driver experience, increases efficiency, and reduces maintenance costs. A rejuvenated, modern fleet requires fewer repairs and has less wear and tear by virtue of being new. New vehicles are covered by manufacturer warranties, which also lowers costs, or can be acquired through full-service leasing, which removes the requirement for in-house maintenance. Optimization through thoughtful decision-making can facilitate the immediate replacement of 5%-15% of the existing fleet.

3. A sustainable fleet

Traditionally, fleets have grown reactively to meet specific, short-term departmental needs, without a central strategy or guidance. The typical result is a disparate fleet, with many overlapping vehicle types and a large number of aging vehicles that are both unpopular with drivers and bad for the environment. At the same time, organizations must meet their own decarbonization targets and set a positive example by sharing their success with customers and communities.

A comprehensive view of their fleet enables companies to deliver on these needs. Decision makers can identify and replace vehicles to create a more modern, sustainable, and efficient fleet that includes EVs and other renewable fuel technologies like hydrogen.

Sustainability requires investments in vehicles and infrastructure (e.g., charging facilities) to help ease adoption. Employees are likely to have concerns that need to be overcome, such as range anxiety (when users worry an EV will not cover their daily journey on a single charge). An analysis of current usage can help convince drivers that EVs will meet distance requirements, particularly as research shows that, in most cases, typical daily needs do not exceed the 250-kilometer range of most modern EVs. Overall, switching away from ICEs positively impacts the environment, the company’s brand reputation, and employee satisfaction.

4. Stronger digital governance

Taking a proactive, centralized approach to fleet management improves governance and efficiency. It delivers improved transparency around demand management, based on quantitative verifiable data, and enables organizations to provide drivers with a better, more efficient experience through a single digital booking system for both vehicles and their maintenance. Beyond this steering, strategic role, a central fleet management team drives operational benefits, including the development of core partnerships with external suppliers to bring down costs.

CENTRALIZING FLEET MANAGEMENT: BEST PRACTICES

In our experience, most organizations have not identified or considered the benefits of centralizing, optimizing, modernizing, and externalizing fleet management. Consequently, companies have not implemented programs to streamline their fleets due to assumptions that the challenges and resources involved will outweigh the financial savings. However, today’s redoubled emphasis on efficiency within companies and the need to decarbonize transport bring fleet management into focus for CFOs and other C-level executives — especially as typical total cost savings from optimization range from 10%-20% and offer the potential to reduce fleet size by 15%-25%.

Successful implementation requires companies to concentrate on four best practices:

- Get senior-level support. Transforming fleet management centralizes activities previously led by individual departments, so a clear mandate and backing from senior leaders is necessary. They must ensure that all business units complete key tasks, such as providing data on usage and needs, and support the entire program as it develops.

- Be pragmatic. Optimizing fleet management will bring savings, but they will not be realized immediately. It takes time and investment to rightsize fleets and internal maintenance operations, renegotiate or end leasing contracts, and add additional infrastructure (e.g., EV charging facilities). Payback should not be expected for at least 12 months.

- Digitalize operations. Previously, fleet management has been an overwhelmingly manual or spreadsheet-driven activity. Full digitalization provides a backbone for more effective governance and easier booking systems, helping fleet management move from being tactical to strategic and reactive to proactive.

- Focus on cultural change. Existing culture remains the biggest challenge to success, as departments are used to having control over their fleets. Managing change is vital and can be achieved by adopting a phased approach to drive engagement, buy-in, and support across different departments for the new fleet management structure.

Conclusion

ACCELERATING CHANGE

Companies have traditionally overlooked the potential to optimize the management of their fleets, believing that the challenges outweigh the potential returns. However, the need to increase efficiency across all operations and to decarbonize transport is now making change a greater priority. To drive success, organizations must:

- Understand current fleets by collecting and aggregating accurate data on usage/demand to give a comprehensive, company-wide view.

- Rightsize assets, focusing on reducing costs and realizing savings while meeting demand and decarbonizing fleets.

- Adopt pooling across the organization to eliminate overlap and departmental silos.

- Implement strong governance processes, backed by senior management support and culture change programs.

- Digitalize operations to improve the user and management experience and deliver transparency and efficiency.