The oil and gas sector has been applying cutting-edge technologies and digital solutions for years but failed to tap the full potential of digital. Companies have been able to sustain these inefficiencies during the period of high oil prices. However, with the increasing market pressures, they must better utilize the available digital applications to remain competitive. Moreover, the COVID-19 crisis is changing the sector, with oil prices plummeting to lows not seen since 1998, forcing oil and gas companies to further accelerate the incorporation of digital solutions.

The oil and gas sector amid the second digital wave: key digital applications and benefits

In the 1990s, the first digital wave started in oil and gas, with companies adopting pilots of digital oilfield projects aimed at leveraging data for real-time monitoring and decision-making. However, terabytes of data were generated by each drilling rig per day, but just a fraction of this information was used for the decision-making. Such inefficiencies have not been possible since the fall in oil prices in 2015.

In the last few years, the oil and gas sector has been going through a difficult period, with a decrease in demand, low oil prices (for longer), and increasing regulatory pressure. It has also faced increased cyber-attacks threatening assets and information. Companies had to reduce costs, improve efficiency and cyber resilience, and maintain margins in order to sustain the difficulties in this sector. Among multiple initiatives, these companies have embarked on the second wave of digital transformation, hoping to stay competitive and improve operations.

Around 10–20 percent of oil and gas industry processes are currently digitized, and a significant increase in digital adoption is expected in the next decade, with approximately 30 R&D programs on “digital oil fields” currently being run by more than 10 leading international companies. Artificial intelligence, machine learning and data analytics, represent the three major digital applications that have been adopted by leading oil and gas companies. Below, we showcase the digital experiences of four national and international oil companies:

Equinor’s digital applications (Norway): Equinor’s strategy emphasizes innovation and digitalization, and the company has been adopting digital applications in its operations for many years. In 2018, Equinor launched the first-ever fully automated, unmanned, remotely operated platform, Oseberg H. The pilot was delivered with more than 20 percent cost reduction compared to the plan, as well as a breakeven price reduction from US$34 to less than US$20 per barrel.

Shell’s digital applications (the Netherlands/global): Shell holds a decade of experience in worldwide smart-field applications, which has enhanced its returns from production by approximately US$5 billion over five years due to digitization of roughly 50 assets. In addition, Shell achieved 50 percent reduction in electrical submersible pump start-up time after trips to Siberia, and 20 percent reduction in travel time to remote assets in the Middle East from numerous smart field applications.

ADNOC’s digital applications (UAE): ADNOC recently launched its 2030 Smart Growth Master Plan to optimize production and achieve gas self-sufficiency, implemented predictive maintenance for 2,500 pieces of rotating equipment through machine learning and AI, and applied blockchain for better transparency in trading and accounting. Moreover, the ultra-sour Ghasha field project is expected to start soon, focusing on digital with smart workers, automation, robots and drones for remote maintenance and surveillance. The project will be managed and operated from a centralized control and monitoring center.

KOC digital applications (Kuwait): Kuwait Oil Company has three major digital projects across its assets (North Kuwait, West Kuwait, and South & East Kuwait), which are still at the pilot phase as part of the Kuwait Integrated Digital Field (KwIDF) program. The aim of this program is to have real-time surveillance of wells and promote collaboration and integration between surface and subsurface groups and teams across KOC. The program also accelerates the data-to-decisions cycle at all levels of the company’s organization through integration of production data and workflows.

Digital applications’ benefits: Incorporating digital applications into the oil and gas sector can lead to multiple benefits:

- Approximately 10 percent increase in production volumes.

- Roughly 1–3 percent reduction in CAPEX for oil and gas projects.

- Around 2–5 percent reduction in OPEX.

- Approximately 5–10 percent reduction in maintenance, repair, and operations inventory (MRO) through real-time tracking and monitoring of inventory and supply chain.

However, oil and gas companies are still facing multiple challenges in adopting and unlocking the full benefits of digital and are still not able to upscale their digital applications.

Key challenges in shifting from pilot to a full-scale digital transformation

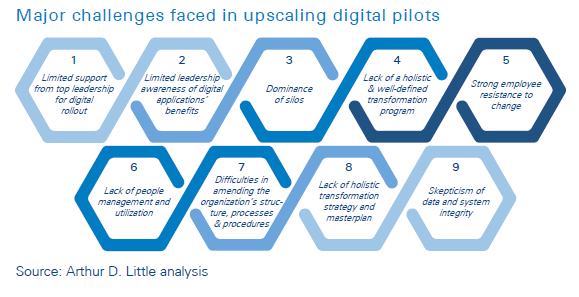

Based on our strong experience and engagements with oil and gas technology and digital transformation projects, as well as interviews with top global digital oil and gas advisors to help NOCs and IOCs upscale digital transformations, we have identified multiple challenges in applying digital to operations:

1. Limited support from top leadership for digital rollout: Digital adoption requires a fundamental shift in how work gets done and, most importantly, how decisions are made at leadership level. The majority of leadership teams in oil and gas companies believe digital transformation is the responsibility of the chief information officer and do not believe that every leader should assume an active role of change manager within their department.

2. Limited leadership awareness of digital applications’ benefits: Leadership has so far struggled to see the benefits of applying digital technologies to the oil and gas value chain due to lack of knowledge and unawareness of the ample applications and uses of digital.

3. Dominance of silos: Top management, unit leaders and heads of departments have always been used to working in silos, setting goals and plans for their own units and departments and never having the urge to collaborate across units or departments. This has encouraged employees to adopt cultures that do not promote technology transfer. Digital transformations, on the contrary, require collaboration and integration across departments for data sharing and analysis, which leads to dismantling of organizational silos. Similarly, in the oil and gas industry as a whole, companies are operating in silos and competing against each other to win the digital race.

4. Lack of holistic and well-defined transformation program: Driving a digital transformation requires a wide-scale progressive effort, which could be challenging to execute. Staff compliance, cultural shifts, people management and utilization, and modifications to systems, processes, and organizations are required. All these changes entail a well-defined transformation approach with dedicated change agents leading the move.

5. Employee resistance to change: Oil and gas employees fear losing their jobs and experiencing sudden changes in their usual ways of working. Technical oil and gas employees also worry about their skills becoming obsolete, and that more work will be required from them to adapt to the new changes, especially when it comes to data-analytics capabilities, which they often lack. Moreover, approximately 27 percent of the workforce in oil and gas is above the age of 55 and might express skepticism about whether introduction of digital applications is required at this stage of their careers.

6. Lack of people management and utilization: Employees will be concerned about their jobs and uncertain about the future ways of working. In addition, firing employees due to automation may not always be possible, especially with employees’ higher awareness of their rights and global dominance of national oil companies (NOCs) with the need to balance generating earnings for their countries and employing nationals.

7. Difficulties amending the organization’s structure, processes and procedures: Oil and gas companies are facing further difficulties in implementing changes within the organization structure, processes, procedures and interactions with operational partners, especially in JVs, as they require time, support and buy-in across their organizations and breaking organizational silos. Some companies are managing the digital transformation with “design digital teams” at the headquarters, and newly hired data scientists and experts, as well as “implementation digital teams” composed of operational employees, at the assets. However, these “parallel structures” could create additional silos and barriers in the organization if either asset’s end-user engagement is late or digital applications designed at the headquarters do not always incorporate end users’ input; this would lead to resistance from asset teams to adopting the application.

8. Lack of a holistic transformation strategy and master plan: Oil and gas companies’ management teams are not developing holistic digital transformation roadmaps and strategies that cut across teams and disjointed pilots. The absence of a holistic digital roadmap, coupled with lack of proper management of digital and technology portfolios, has resulted in several irrational digital investments and initiatives across the sector. This has been especially impactful with the unavailability of a proper financial assessment of solutions in terms of compliance with international norms, rules and standards. Companies have mostly adopted innovation on a small scale, with strategies and plans set for separate pilots, which has led teams and units to keep operating in silos.

9. Skepticism of data and system integrity: Some leaders and employees have questioned input data quality, the integrity of data handling and integration from different departments, and the outcome from visualization centers and dashboards. The limited trust in the outcome has led some employees to maintain their old ways of working through standard and basic models and spreadsheets.

Key solutions for oil and gas companies to upscale their digital transformations

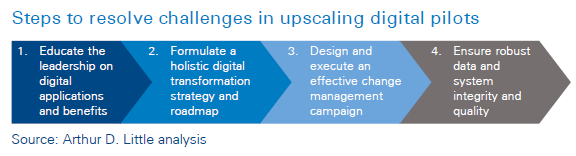

1. Educate leadership on digital: Leaders are responsible for setting a clear path for digital transformation and must implement the change. They should shift their mind-sets to realize that the sector is changing, and digital transformation is not the role of the CIO only. Leaders should not only raise awareness and promote digital shift, but also adopt digital in their day-to-day activities.

Leaders should be well educated about the available digital applications in the market, their benefits, and the added value they bring to the organization from cost savings and increases in efficiency. Moreover, they should also learn from other industries such as telecom, healthcare, and aerospace about the benefits captured by first adopters of digital and the tremendous losses faced by laggards.

2. Formulate a holistic digital transformation strategy and master plan: These should link all internal digital programs and mega-projects based on business needs. All existing digital initiatives, lessons learned from these initiatives, and capabilities within the company should be mapped and included in the master plan as part of a holistic digital portfolio, with digital initiatives organized and prioritized based on their added value and financial feasibility. Furthermore, the master plan should include clear KPIs for digital transformation implementation for all relevant stakeholders to ensure accountability and timely delivery of initiatives.

3. Design and execute an effective change management and communication campaign: The change management campaign should be aligned with the overall company digital masterplan and led by the leadership, who should play the role of change champions. They should communicate the transformation plan, ambitions, and benefits to employees and get support from experts in oil and gas digital to transfer technical know-how to the organization.

The organization structure and processes should also be revised to incorporate digital changes without creating “parallel structures” within the organization. Data scientists and engineers should be collocated at the assets to ensure a collaborative and effective design to the implementation process.

4. Ensure robust data and system integrity and quality: Robust data and system architecture should be put in place to ensure the quality of the digital platform outcome is good and, consequently, secure end users’ trust. To achieve a robust architecture, companies should have multiple trials and simulations on the system, better structure, and integration of real-time data from different departments, and effectively manage large analytical models.

How can Arthur D. Little (ADL) support leading oil and gas companies in their digital transformations

Since the 1960s, Arthur D. Little has been the agenda shaper of the oil and gas sector, particularly due to setting up multiple NOCs and supporting them in their transformations. Our historical relationship with leading oil and gas companies puts us in a great position to shape the future of oil companies, especially to support them in their digital transformations through:

Strategy and master plan development: Develop your holistic digital strategy and master plan, linking all your existing and future digital initiatives.

Change management design and execution: Develop and support your company in executing your change management plan through our “ADL Scale-up Engine” to move from pilots to full scale. This approach will include quantification of benefits realized, communication of benefits to the entire organization to increase acceptance and adoption, and communication of best practices from digital applications at other companies (oil and gas and other sectors) to increase your company’s know-how in digital.

Digital processes and organization assessment and design: Review and revise your processes and organization structure to put them in line with your digital strategy.

Post-execution digital health checks: Conduct regular health checks after execution of digital projects, based on 10 key dimensions, as part of our “Digital Shift Health Check”

Case study: Digital oil field pilot… from success to significance!

We ran a four-year digital upscaling pilot program with more than 150 wells networked on one of the largest producing fields in the world. The latter was struggling from constrained production, which had resulted from limited wet crude oil-handling capacity, lack of accurate well integrity performance, and uncertain subsurface reservoir characteristics.

Our major objectives relied on:

- Optimizing production by identifying water encroachment in wells and enabling the company to react and control.

- Optimizing capacity by enhancing current and future production capacity to provide a sustainable oil rate.

- Data collaboration by improving data integrity, visibility, communication and knowledge sharing.

We consequently implemented our digital transformation framework, the “ADL Scale-up Engine”, which focused on upscaling operations. It included both intelligent fields with smart monitoring systems, real-time data and solar panel-powered systems, digital controls with a collaboration center (covering operations, drilling and subsurface), daily production optimization, life-of-well information, a production-monitoring system, and easy and smart visualization tools.

Our pilot program has succeeded in creating integrated decisions and delivering one upscaled and connected system of intelligent operations and asset management, collaborative workforce and digital supply chain.